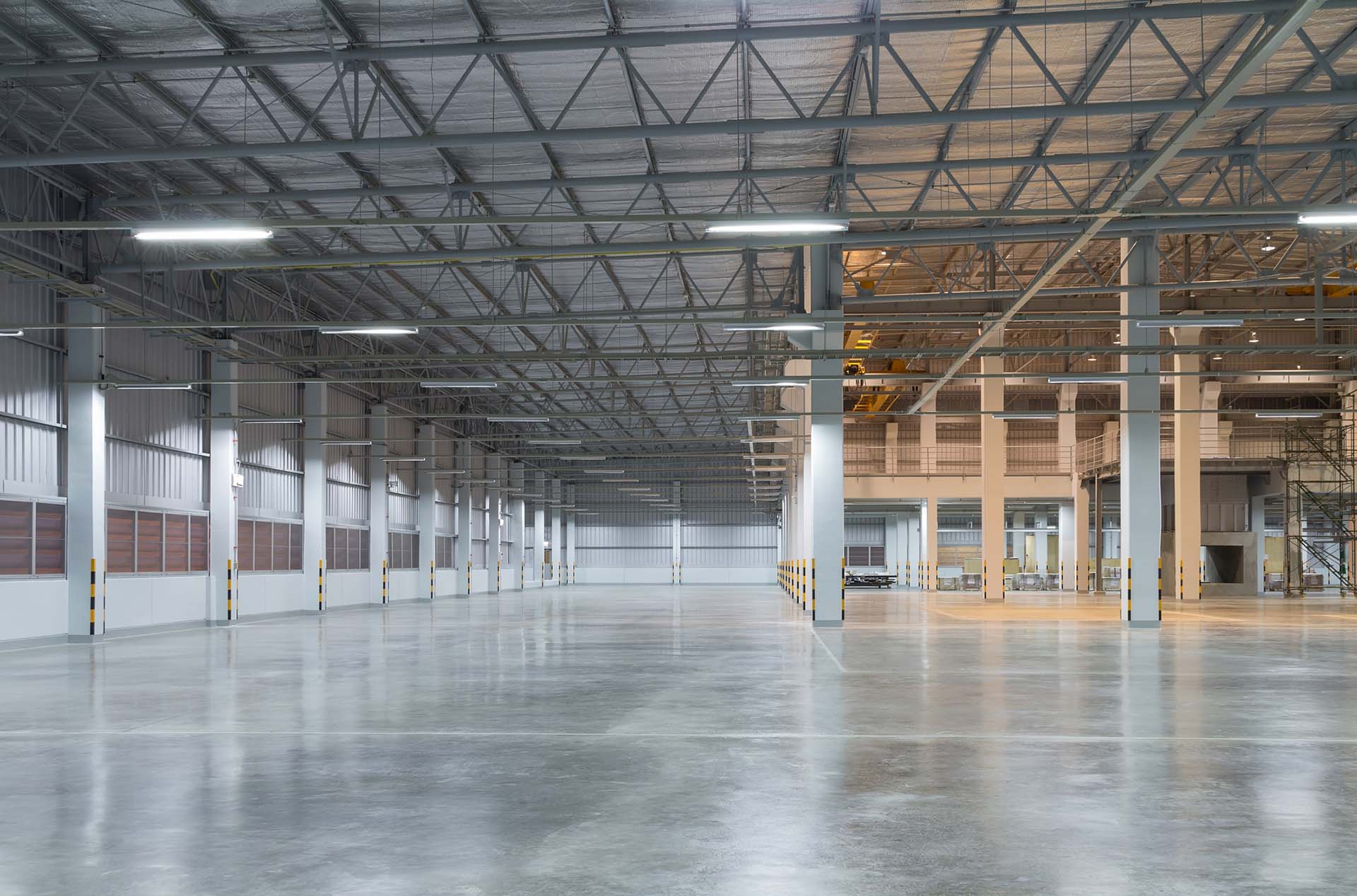

Industrial Concrete Floors

We construct industrial-grade concrete floors for manufacturing plants, food processing facilities, and heavy industrial operations. Our floors handle extreme loads, chemical exposure, and demanding production environments.

Floors Built for Industrial Operations

Manufacturing facility owners and industrial property developers rely on our expertise for floors that perform under harsh conditions.

Chemical Resistance

Epoxy and urethane coatings protect concrete from oils, acids, and industrial chemicals. We match coating systems to your process requirements.

Heavy Equipment Support

Our floors support CNC machines, presses, and heavy manufacturing equipment. Proper thickness and reinforcement prevent settlement.

Drainage & Containment

Trench drains, slope-to-drain floors, and secondary containment meet environmental and safety requirements.

Non-Slip Safety Surfaces

Textured finishes and anti-slip coatings protect workers in wet or oily environments. We meet OSHA walking surface requirements.

Turnkey Industrial Concrete Floors Execution

As your general contractor, we manage every detail from initial bid through project completion. One accountable partner for your entire scope.

Process Analysis

We review your manufacturing process, equipment, and chemical exposure to specify the right floor system.

Structural Design

Floor thickness, reinforcement, and joint layout are engineered for your equipment loads and building structure.

Concrete Placement

Proper sloping, equipment pads, and embedded anchors are placed during concrete work. We coordinate with your equipment vendors.

Surface Treatment

Hardeners, densifiers, or coating systems are applied based on your operational requirements and budget.

Your General Contractor—Not a Subcontractor

We work directly with property owners, developers, and facility managers. You get a single point of accountability and competitive pricing without subcontractor markups.

Property Developers

Commercial real estate developers building retail, office, and industrial properties.

Facility Owners

Industrial, healthcare, and institutional facility owners expanding or renovating.

Commercial Landlords

Property owners seeking tenant improvements and building upgrades.

End Users

Businesses building or renovating their own facilities with direct ownership.

Ready to Bid Your Industrial Concrete Floors Project?

We work directly with property developers and facility owners—no subcontracting layers. Contact our project executives for competitive pricing and a detailed execution plan.

Service Areas

- Carrollton, TXAvailable

- Lewisville, TXAvailable

- The Colony, TXAvailable

- Farmers Branch, TXAvailable

- Addison, TXAvailable

- North Dallas CorridorAvailable

Industrial Concrete Floors FAQs

Common questions from developers and property owners about our industrial concrete floors services in Carrollton and North Dallas.

What floor systems work for food processing?

Food facilities require seamless, easily cleanable floors with proper drainage. Urethane coatings over concrete provide the durability and sanitation food processors need.

How do you handle equipment anchor bolts and pads?

We coordinate with your equipment suppliers on anchor bolt patterns and machine pad dimensions. Embedded items are placed during concrete work for accurate positioning.

Can you build floors that handle heavy forklift traffic?

Yes. We use harder concrete mixes, armored joints, and surface hardeners to resist abrasion from loaded forklifts and pallet jacks.

What about anti-static floors for electronics manufacturing?

Conductive and static-dissipative floor systems are available for electronics facilities. We work with specialty coating suppliers for ESD-compliant floors.